1 / 3

1 / 33D printing with PROTOWORX and igus components

Preço do Hardware:

construction

DIY

accuracy

0,1

mm

Hotend

250°C

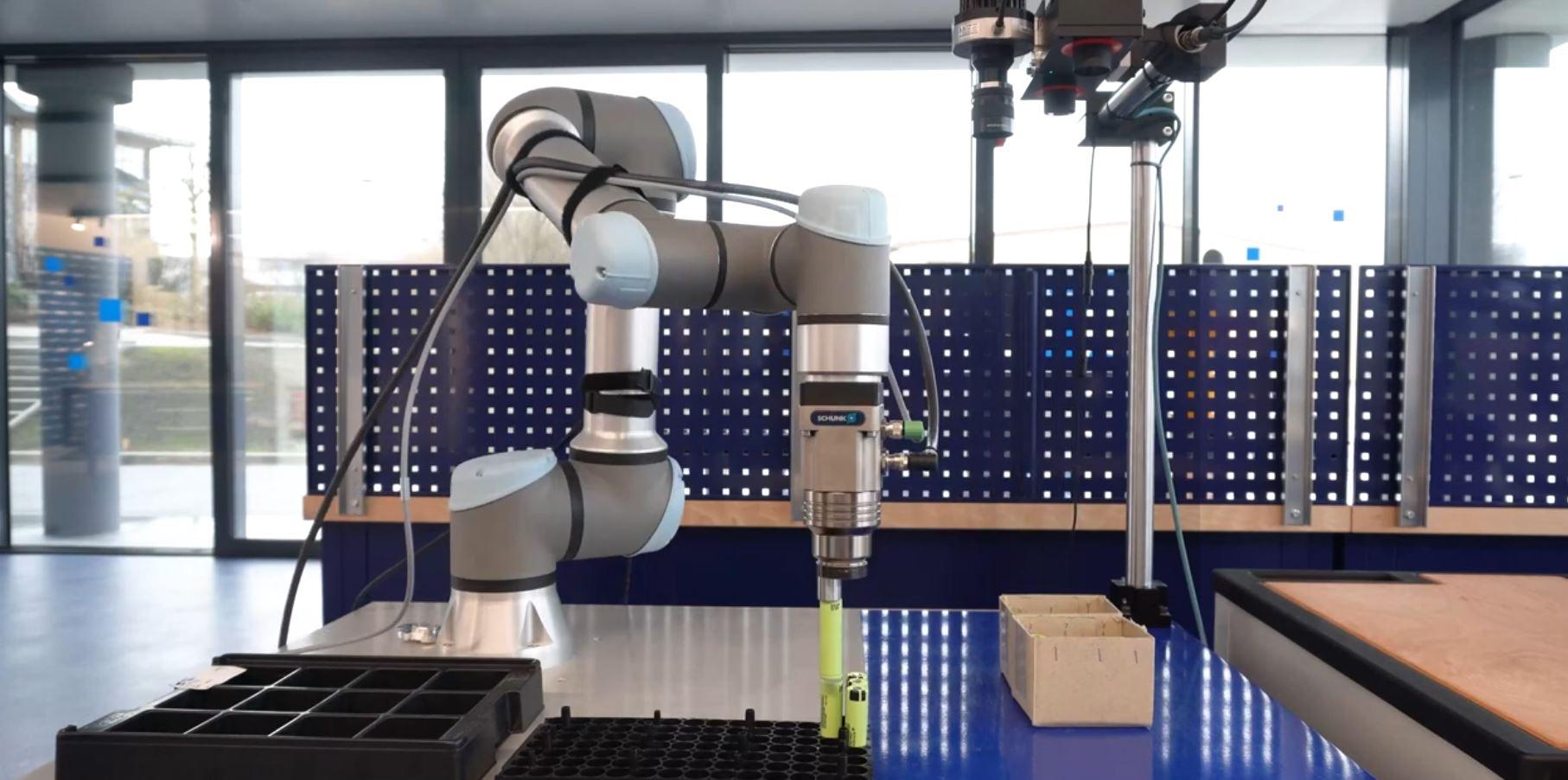

The high-precision 3D printer from Protoworx at the Hanover trade show

Every year, international companies can exhibit their products and applications for many different industrial sectors at the world's largest trade fair, the Hannover Messe.

igus annually presents product innovations at the Hannover Messe, which are developed over the course of the year. To show where and in which applications and industries igus can be found, igus offers several companies that use igus products in their applications, the chance to showcase their products at the igus booth.

Protoworx integrates linear guides, energy chains as well as printing materials from igus into their 3D printers. These products enable a maintenance-free, insensitive and very reliable production machine with smooth running.

Among other products at the trade show was their TINY V2 3D printer. The 3D printer is particularly impressive due to its high precision at fast printing speeds. A resolution of 1,280 steps per millimeter on X and Y and up to 3,200 steps per millimeter on the Z axis is possible. Frame dimensions of 20x20x40cm make the TINY V2 the perfect mobile printer. The printer can also be moved during production. By using a room linear robot from igus with its drylin rails and bearing housings with corresponding bearing foils, it was possible to achieve play-free guidance of the axes, which can easily withstand even long-lasting, rapid loads and movements, thus enabling fast, high-precision 3D printing. The ribbon cables on the heating bed and extruder are also constantly exposed to these movements and must therefore be guided with as little stress as possible. The ribbon cables could be guided gently by using igus energy chains. In this way, cable breaks are prevented and the wear of the cables is reduced to a minimum.

1 Componente