“The monitoring systems have significantly reduced the error rate."

Richard Kremser

Meleghy Automotive GmbH & Co. KG – Wilnsdorf, Germany

RBTX Facts

Efficiency

Output doubled; less staff needed

Error rate state

Lower error rates in production

Integration

Easy, stable implementation

Scalability

High

In a nutshell

Meleghy Automotive’s automation project highlights the Dobot Nova 2 robot's potential to transform manufacturing. By automating a manual buck welding system for galvanized sheets, the company boosted efficiency, doubling production output with reduced manpower. The Dobot Nova 2 ensures precise and consistent quality, significantly lowering error rates through advanced process monitoring. Its seamless integration underscores the scalability and adaptability of modern robotics across various operations. Leveraging the cost-effectiveness of RBTX-components, Meleghy Automotive achieved notable improvements, making automation accessible. Inspired by this success, the company plans further developments, ushering in a more efficient, reliable, and innovative manufacturing era.

The challenges: efficiency, precision and reliability

Meleghy Automotive faced unique challenges in automating its buck welding process for galvanized sheets. The goal: improve efficiency and reduce errors while maintaining high-quality standards.

Efficiency meets complexity:

Transitioning from manual labor to automation required overcoming various obstacles:

- Ensuring seamless robotic handling of parts to avoid production bottlenecks.

- Doubling production output while minimizing manpower.

- Maintaining consistent operation across varying conditions.

Precision meets reliability

Advanced process monitoring was needed to ensure:

- Accurate placement and welding of nuts.

- Significant reduction of errors and rework.

By leveraging Dobot Nova 2’s adaptability and efficiency, alongside RBTX-components, Meleghy Automotive has addressed these challenges, creating a reliable, cost-effective manufacturing solution.

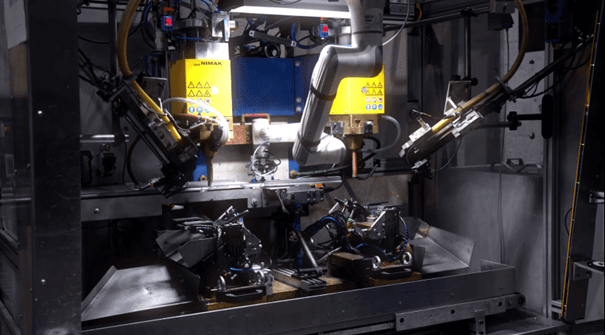

The solution: Automated buck welding with precision and efficiency

To enhance manufacturing processes, Meleghy Automotive implemented the Dobot Nova 2 robot to automate buck welding of galvanized sheets. This innovative system replaces manual labor, doubling production output while reducing human resource requirements. It ensures consistent welding precision and significantly lowers error rates through advanced monitoring features.

The Dobot Nova 2 robot is paired with modular RBTX-components, offering flexibility for seamless integration into existing workflows. Its adaptability makes the solution scalable and suitable for various production needs, ensuring long-term reliability.

By streamlining operations and improving overall quality, Meleghy Automotive delivers a cost-effective, efficient, and sustainable approach to manufacturing. This automation highlights how robotics technology can be transformational, providing measurable benefits across the entire production cycle.

Key facts

Robot Model

Dobot Nova 2

Tasks automated

Buck welding of galvanized sheets

Precision

0.05 mm

Max. speed

1.6 m/s

Conclusion

Meleghy Automotive’s automated buck welding system represents more than just a technical upgrade – it showcases how robotics can transform manufacturing for efficiency, precision, and sustainability. By automating labor-intensive welding tasks with the Dobot Nova 2 robot, the company illustrates how targeted innovation can boost productivity, enhance quality, and reduce errors.

The decision to use modular and cost-effective RBTX-components was strategic: moving away from manual-heavy operations to accessible, scalable automation technology. This shift makes modern robotics viable for a variety of production needs.

The result is a streamlined manufacturing system that reduces labor dependency, improves quality, and enhances scalability. Meleghy Automotive demonstrates how advanced automation can revolutionize traditional industries while ensuring efficiency and long-term reliability.