1 / 6

1 / 6Labeling line for farm ice cream

Hardware Price:

ROI

3

months

Cycle time

3.5

seconds

Max. velocity

0.5

meters per second

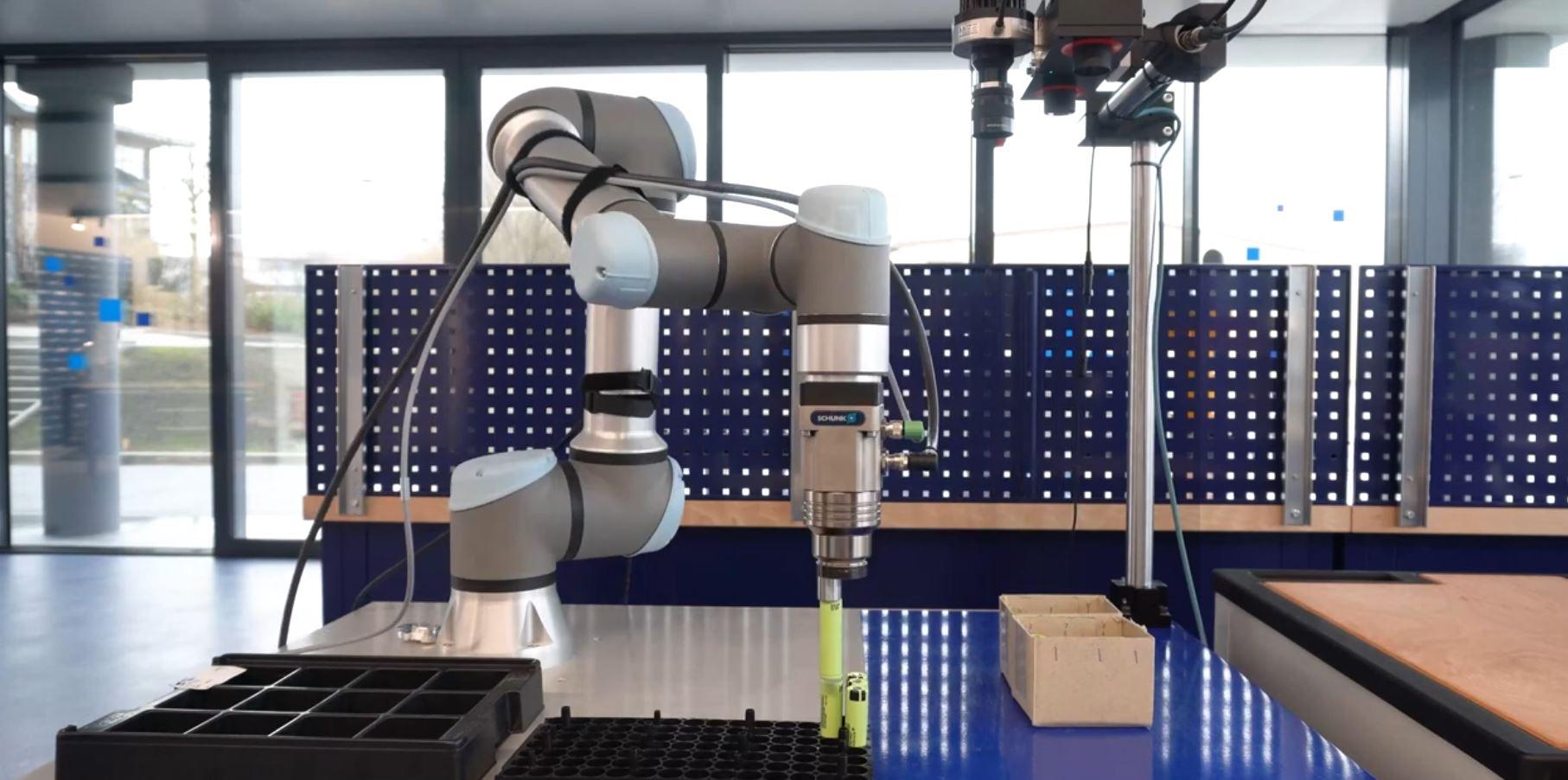

Automated Labeling for Farm Ice Cream with igus drylin® Axles

Efficient and flexible labeling is essential for small-scale food production. At the Beindlhof farm in Wackersberg, an automated labeling machine ensures precise application of labels on "farm ice cream" cups while also closing them. The system integrates igus drylin® drive axles, enabling seamless operation and flexibility. With the ability to manage 200 label types during operation, this solution optimizes production workflows, saves time, and reduces labor costs.

What is the Application?

The system automates closing and labeling ice cream cups while distinguishing between 200 label types in real-time, eliminating the need for manual intervention or pre-printed labels.

What are the Advantages of the Solution?

Increased Production Flexibility: Handles diverse label requirements efficiently.

Cost Savings: Replaces the need for a seasonal worker.

Time Efficiency: Eliminates preparatory label printing, speeding up processes.

What are the Advantages of the Robot?

The igus drylin® drive axles contribute to reliable performance:

Durability: Maintenance-free design ensures long-lasting operation.

Precision Motion: Guarantees accurate label placement.

Compact Size: Fits seamlessly into small farm production setups.

Streamlining Farm-Based Ice Cream Labeling

The automated labeling machine with igus drylin® technology transforms farm-based production, offering flexibility, cost efficiency, and time savings. By automating the labeling and cup-closing process, Beindlhof has optimized workflows, reduced labor dependency, and elevated product consistency, ideal for modern farms.

2 Components